版权所有©上海普容尼精密模具有限公司。 备案号:沪ICP备17040593号-2 专注精密模具加工,精密零部件加工,注塑模具制造;质量保证,价格公道,欢迎前来洽谈。

版权所有©上海普容尼精密模具有限公司。 备案号:沪ICP备17040593号-2 专注精密模具加工,精密零部件加工,注塑模具制造;质量保证,价格公道,欢迎前来洽谈。

Products

Products Center

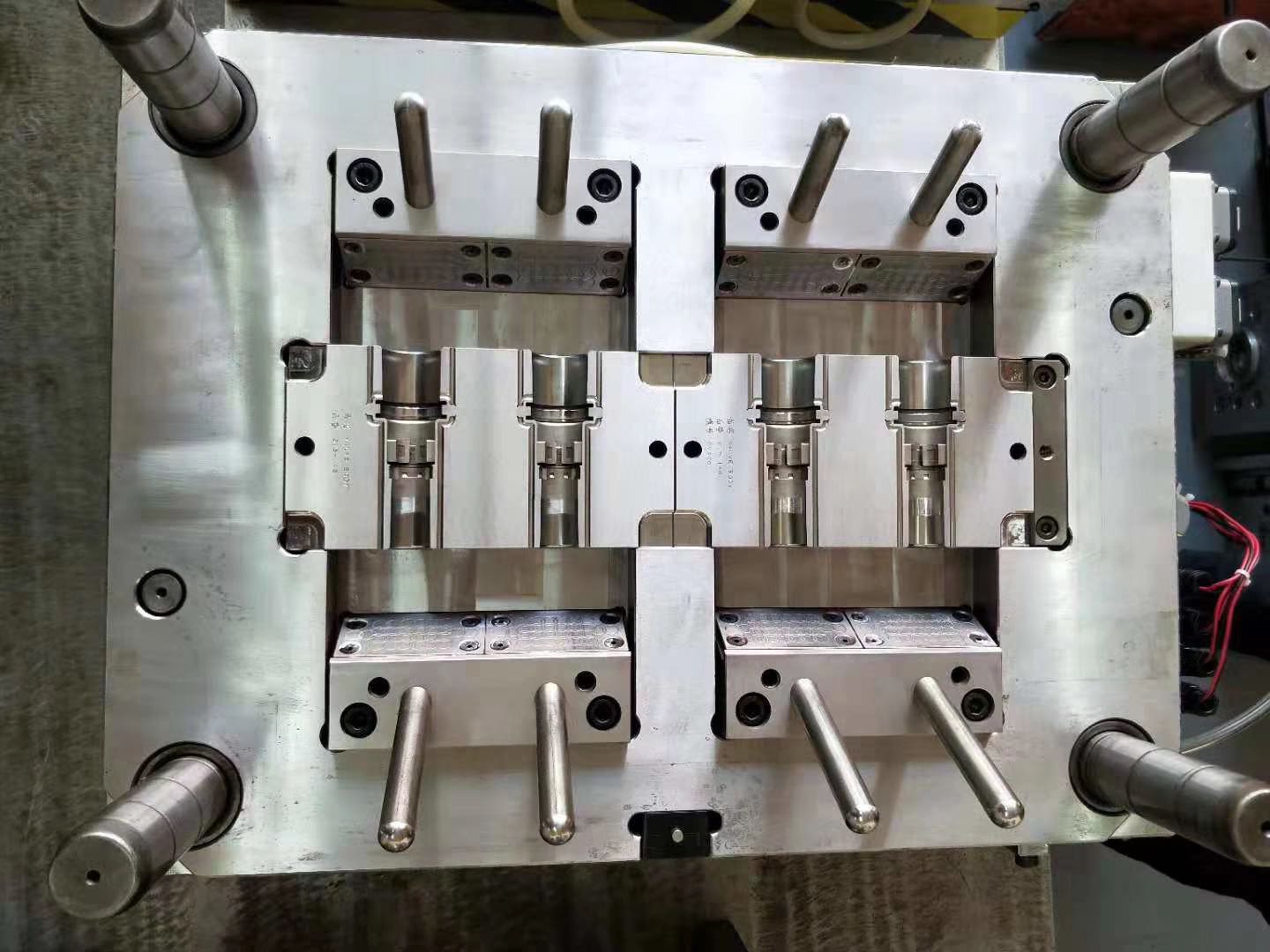

ObjectCosmetics fieldmaterialABS, PC, PET, PP, PE, etc.In order to meet the quality needs of customers, based on a full understanding of the use of th...

ObjectHome appliance fieldmaterialABS, PC, POM, PBT, PPO, PA6, PIM, etc. (including GF)Actively participate in customers product development plans and...

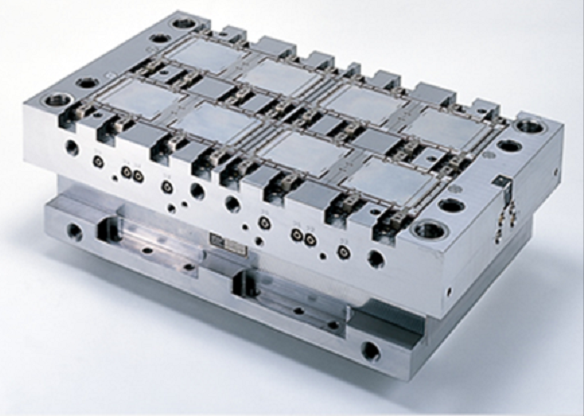

ObjectAutomotive fieldmaterialPPS, PA, POM, PBT, PPO, etc. (including GF)Through the research and development of high-capacity molds (multiple cavitie...

Objectmedical fieldmaterialPPS, PES, LDPE, LPC, PE, etc.Advocating a high-strength product shape and a quality management concept that fully understan...

ObjectConnector fieldmaterialABS, PC, PET, PP, PE, etc.In order to meet the quality needs of customers, based on a full understanding of the use of th...

ObjectConsumer ElectronicsmaterialABS, PC, POM, PBT, PPO, PA6, PIM, etc. (including GF)Actively participate in customers product development plans and...

如果您有什么问题,可以直接拨打我们免费客服热线

About

ABOUT US

Shanghai Mold Processing and Design Manufacturer-Shanghai Puroni Precision Mold Co., Ltd. is a Japanese-funded enterprise established in 2005 and currently has 52 employees.

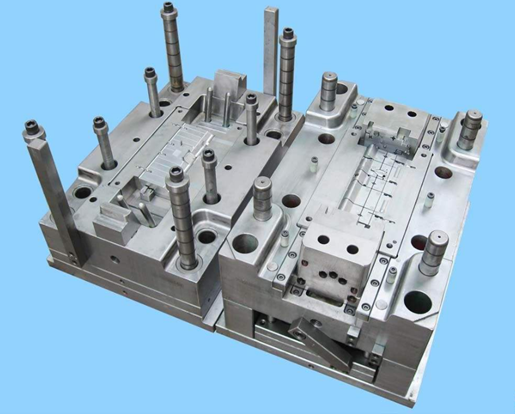

Our company is a professional manufacturer of precision mold processing, injection molding, injection molds, precision injection products and precision parts processing.

The company introduces advanced mold processing equipment and injection molding equipment from Japan, and has a team of professional engineers and technicians, and effective management ensures mold quality and professional services.

Now our customers are mainly distributed in Europe and America such as China, Japan and France.

Our core advantage

01

02

03

04

Mold customization process

Mold customization process

Order acceptance

Mold design

Mold processing

Injection production

Product assembly

Product testing

Package

News

News Center

注塑成型以后可能会出现各种各样的问题,但这都是避免不了的,一旦有这些问题就会影响成品的使用效果,并且不能满足公司的需求,那么我们就要在制作完成前将这些问题给找出来,查看下到底是哪个步骤出了问题,下面就给大家讲讲注塑成型以后色彩的问题。(1)注塑机的匹配首先选择注塑成型机器的时候要选择与产品相符的设备...

注塑模具是一个技术工作,并且与其他加工技术不相同,当使用注塑技术时,要根据不同的模具选择不同的材料以及使用不同的注塑成型工艺,这就是注塑模具的与众不同,对原料、特性以及模具都有不相同的规定。1.随着高速成型机械设备的出现,塑料制品的生产速度加快。由于注塑模具温度通常在165-300°c 之间,有些零件流动...

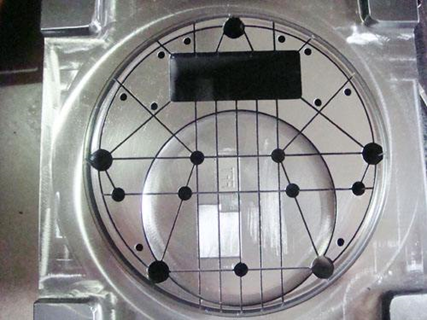

1.模具加工精度要求高:一个成品模具是由很多部位组成的,并且有些模具还是通过复杂的拼接而成的,所以模具加工过程中需要对各个拼接部位着重要求加工精度,不然上下模和型腔是组合不起来的。2.模具轮廓复杂:某些产品,如汽车面板,飞机部件,玩具,家电,其表面形状形成多个弯曲表面的组合,因此,模腔表面是非常复杂的。...

注塑模具是指将一个模具通过注塑的形式加工出来,但是这个过程如果把握不好容易使材料损坏;并且如果注塑模具工具使用久了并没有仔细维护保养,也容易出现损坏的现象,也会对公司造成损失,那么损坏的原因都有哪些呢?那么,注塑成型模具为什么会损坏呢?大家都在组装时已知的注射模具,没有太大的力从外部施加,但一旦安装...

版权所有©上海普容尼精密模具有限公司。 备案号:沪ICP备17040593号-2 专注精密模具加工,精密零部件加工,注塑模具制造;质量保证,价格公道,欢迎前来洽谈。

版权所有©上海普容尼精密模具有限公司。 备案号:沪ICP备17040593号-2 专注精密模具加工,精密零部件加工,注塑模具制造;质量保证,价格公道,欢迎前来洽谈。